Sonda di misura a scansione per macchine utensili SPRINT™

Sfrutta al massimo la velocità e l'accuratezza delle sonde di scansione per macchine utensili Renishaw con tecnologia SPRINT. Le nostre sonde di scansione per macchine CNC sono prodotti esclusivi che permettono di acquisire dati 3D con grandissima accuratezza, per portare i tuoi processi produttivi a un nuovo livello.

Le scansioni a bordo macchina ottimizzano i processi produttivi

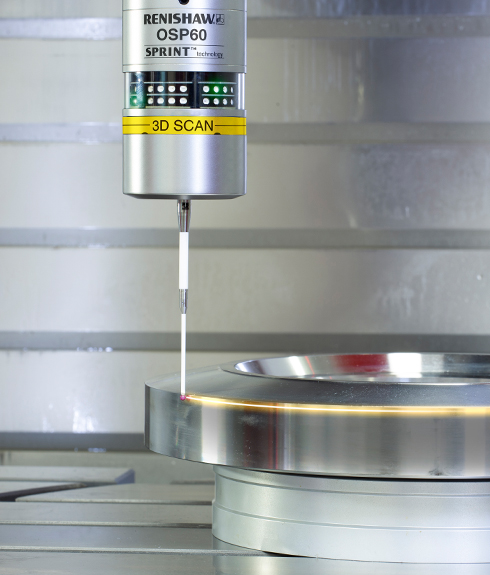

Grazie agli esclusivi sensori 3D, la sonda di scansione OSP60 con tecnologia SPRINT offre agli utenti di macchine CNC prestazioni di ispezione impareggiabili.

La nostra sonda di scansione risponde in modo eccellente alle variazioni superficiali ed è in grado di rilevare spostamenti della punta dello stilo inferiori al micron, acquisendo 1.000 punti dati 3D al secondo. Include funzioni di misura dei punti e scansione di alta precisione e rappresenta la soluzione ideale per moltissime applicazioni industriali.

Funzionalità utilissime:

- Misure dei pezzi estremamente rapide. Le scansioni assicurano un incredibile risparmio di tempo durante le ispezioni con macchina e l'impostazione dei lavori, massimizzando i tempi di attività e la produzione.

- Determinazione della forma dell'elemento. Determinazione del punto alto/punto basso della superficie o misura della forma dell'intero elemento.

- Controllo durante il processo. Acquisizione dei risultati di misura del pezzo e controllo automatico dei processi in macchina. Stampa dei risultati per approfondire le analisi o per operazioni di controllo qualità.

Ispezioni flessibili e versatili

La scansione in macchina consente di svolgere operazioni di ispezione che in precedenza risultavano impossibili o che richiedevano tempi molto lunghi. Permette inoltre di acquisire informazioni più dettagliate durante i processi produttivi.

La tecnologia Renishaw fornisce misure 3D a contatto estremamente accurate e scansioni 3D veloci e ad alta densità, per ottimizzare i tempi ciclo complessivi e incrementare la produttività delle macchine presenti in officina.

La sonda per macchine utensili OSP60 è uno strumento molto flessibile e permette di utilizzare la stessa configurazione di stili per impostazioni pezzo, verifiche in-process, adattamenti 3D, lavorazioni adattive e monitoraggio delle condizioni della superficie. Porta la tua produttività a un livello superiore, installando un sistema di scansione in macchina.

L'investimento ha prodotto risultati ben al di sopra delle nostre più rosee aspettative. L'accuratezza durante la fresatura dei dischi per palette è migliorata di oltre quattro volte, mentre i costi di manodopera si sono dimezzati.

Technopark Aviation Technologies

Una sonda dalle potenzialità infinite

Impostazione pezzo ad alta velocità

Usa i punti di contatto o i cicli di scansione per impostare il pezzo in tempi rapidi. Utilizza i risultati per impostare o aggiornare le origini pezzo. Imprescindibile per le produzioni di grandi volumi, specialmente nei settori automotive, medicale e dell'elettronica di consumo.

Adattamento degli elementi 3D

Misura elementi 3D quali coni, cilindri, sfere o sezioni circolari, utilizzando più percorsi di scansione. Utilizza i dati ottenuti per eseguire operazioni di adattamento prima della lavorazione. Offre una strategia di scansione flessibile per i pezzi con elementi interrotti o incompleti.

Acquisizione di superfici 3D

Ispezioni rapide di componenti con geometrie complesse, a forma libera, comuni nei settori aerospace e medicale (bordi anteriori e posteriori delle palette, giranti, componenti tibiali e giunti femorali). Estremamente utile anche nei settori dell'energia.

Lavorazione adattiva

Generazione di percorsi di taglio specifici per ciascun componente al fine di tagliare pezzi quasi perfetti. Regolando il punto nominale del percorso utensile, è possibile ottenere una corrispondenza con la forma reale del componente scansionato. Ideale per operazioni di sbavatura e taglio degli smussi. Semplifica drasticamente le applicazioni di tipo copia/incolla.

Monitoraggio delle condizioni della superficie

Le macro di misura dedicate aiutano a determinare le condizioni della superficie del componente e a rilevare ondulazioni eccessive, creste e gradini. Essenziale per guarnizioni e superfici combacianti in applicazioni in cui la tenuta ermetica è un fattore critico.

Analisi dello stato della macchina

Verifica le prestazioni della macchina utensile in meno di un minuto. Integra i cicli in programmi di lavoro per CNC per garantire che le condizioni e le prestazioni della macchina siano adeguate prima di avviare la produzione di componenti critici.

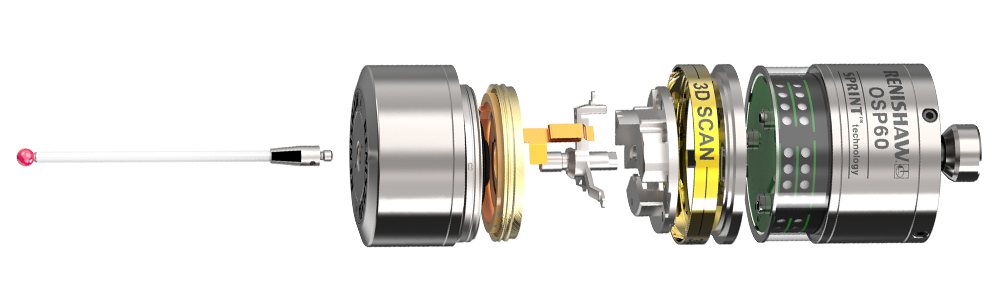

Innovativa tecnologia SPRINT

La sonda OSP60 con tecnologia SPRINT sfrutta un design con due molle planari che consente di misurare l'ampiezza totale della deflessione 3D e i componenti della direzione XYZ. In questo modo, la sonda può rispondere in modo ottimale alle variazioni della superficie, abilitando misure veloci e accurate di superfici complesse, prismatiche e a forma libera.

Due anelli concentrici sono installati all'interno della sonda: uno fissato al corpo e un secondo, fissato sul supporto, che si sposta insieme allo stilo. Le misure di capacitanza fra i circuiti degli anelli permettono alla sonda di registrare le deflessioni dello stilo con estrema accuratezza.

Un software di scansione molto potente

La sonda OSP60 è adatta per tantissime applicazioni industriali e consente di adottare un approccio flessibile alla programmazione. Le opzioni includono applicazioni tradizionali e basate su macro, soluzioni in stile CAD/CAM e interfacce utente grafiche (GUI). Questa varietà di scelte rende la scansione in macchina una soluzione accessibile anche per chi non ha un'esperienza approfondita in fatto di programmazione.

Tutte le opzioni di programmazione supportano le misure prismatiche come standard. Sono disponibili pacchetti aggiuntivi, studiati per supportare applicazioni industriali specifiche ed estendere le capacità del sistema.

I risultati delle misure possono essere salvati nelle variabili macchina, esportati in un file oppure inviati ai pacchetti di reportistica Renishaw. Renishaw Central, Scan Data Viewer e MODUS CHART supportano la visualizzazione dei dati di misura scansionati.

La compatibilità con software di reportistica e analisi di terze parti contribuisce ad ampliare ulteriormente la flessibilità e la capacità del sistema di scansione.

Per maggiori informazioni sul nostro software di ispezione, è possibilescaricare la brochure.

Passi successivi

Per richiedere altre informazioni o effettuare acquisti, invia il modulo per contattare l'ufficio Renishaw di zona.

ContattiDownload

Brochure

Schede tecniche

Note di capacità

Cerchi assistenza?

Contattaci o visita la nostra libreria di articoli tecnici contenente una vasta scelta di schede tecniche, manuali di installazione, guide all'uso e informazioni sulla conformità.